Production Optimization with IoT and AI

IoTAISoftware

30% reduction in production time through the implementation of an integrated real-time monitoring and optimization system.

30% reduction in production time through the implementation of an integrated real-time monitoring and optimization system.

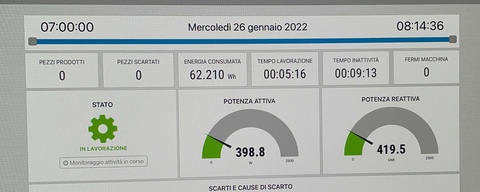

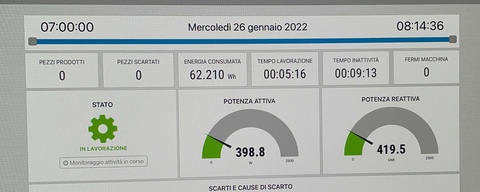

The client needed to optimize production processes by reducing downtime and improving the overall efficiency of the production line.

We developed an integrated system that combines:

30%

Reduction in production time

45%

Reduction in machine downtime

25%

Energy savings

The implementation of the optimization system has completely transformed our production. Real-time visibility and AI predictions have allowed us to make more informed decisions and significantly reduce operational costs.

Metal Carpentry

Operations Director

Discover how we can help you achieve similar results with a customized solution for your company